Smart Automation Application

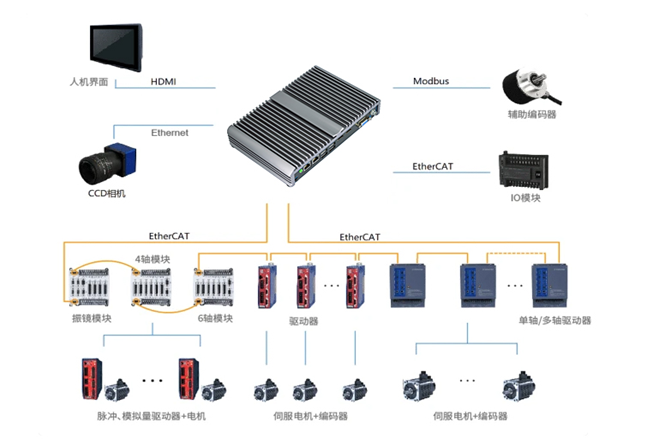

As the network technology has been widely applied in manufacturing, the CNC lathes can also be networked now. GIFA’s embedded industrial computers have outstanding computing power and network control capabilities and do excellent job in the field of CNC machine.

How it works

A CNC machine equipped with an industrial computer only needs to change the input program instructions when the processing target is changed. It can accurately process complex surfaces. Therefore, it is suitable for processing small and medium batches, frequent modifications, Workpieces with high precision requirements and complex shapes.

The industrial computer integrates the input and output devices in the traditional CNC machine with the functions of the control center, which easily solves the problems of human-machine interface, programming, network communication and so on. Based on the advantages of stable performance, easy operation, convenient maintenance and low cost, more and more CNC manufacturers choose industrial computer as the front-end computer of CNC machine.

GF-603U designed for CNC manufacturing and industrial automation

▶Using Intel® Sky Lake-U Core i3-6100U processor (optional i3, i5, i7)

▶DDR4 4GB memory, up to 32GB dual-channel

▶2×Intel high-performance Gigabit LAN

▶1×128GB M.2 SSD solid state drive

▶2×HDMI, 1×VGA, of which HDMI2 and VGA can be used either

▶1×Mini-PCIe expansion slot, can expand WIFI, 3G/4G

▶Support watchdog, wake-on-lan, diskless boot and other functions

▶Aluminum alloy, sheet metal chassis, with good anti-rust, anti-corrosion, heat dissipation performance

▶Suitable for IoT, control, industry 4.0 and other applications

By continuing to use the site you agree to our privacy policy Terms and Conditions.